The building design and construction process is an amalgamation of various complex systems and processes for its successful and satisfactory completion. MEP (Mechanical, Electrical, and Plumbing) systems are one of these systems that play a critical role in a building’s functionality.

MEP shop drawings are a stepping stone for the successful installation of MEP systems, making Shop Drawing services a significant part of the whole process. These services ensure the availability of detailed information about the fabrication and installation of MEP systems with the stakeholders during all stages.

Shop drawing services facilitate a seamless fabrication, assembly, installation, and maintenance of the MEP system of the built form. The 2021 industry study suggests a surge in the MEP market at a compound growth rate of 16% between 2020-2024. MEP components are crucial for every project, irrespective of the project type and design, forming the backbone of the construction industry.

What are MEP Shop Drawings?

Shop drawings are detailed diagrams that provide information about the Mechanical, Electrical, and Plumbing systems and their installations of a building.

These drawings are created by MEP engineers and used by architects, designers, and contractors to coordinate design, fabrication, and site execution. The drawings ensure that all components are skillfully procured and installed as per building standards and codes.

The accuracy and precision of MEP shop drawings ensure that the cost and performance of a project are maximized. Generating MEP shop drawings is a crucial step in the design process to avoid a chaotic installation process. The drawings entail critical information about materials, equipment details, and installation procedures, significant to the construction process.

Shop drawing services are a way of ensuring that the project is constructed as per the agreed specifications gradually enhancing coordination among stakeholders. MEP shop drawings are generated typically in two different forms.

One is the material and equipment shop drawing submittals, which are shared with concerned professionals to ensure that these elements intended to be purchased comply with the design intent. The second form of drawings is installation shop drawings used by contractors to ensure coordinated installation on site.

The details and information included in each set of drawings are as follows:

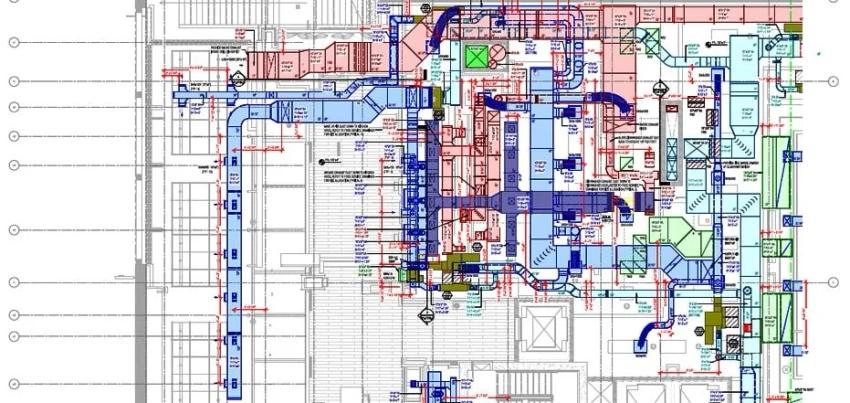

Mechanical Shop Drawing

These drawings entail the specifications and location of HVAC (Heating, Ventilation, and Air Conditioning) systems. The information is inclusive of details about installing and fabricating ducts, customized piping, and air-handling units.

Mechanical drawings also represent transportation systems like lifts, escalators, industrial, and infrastructural components.

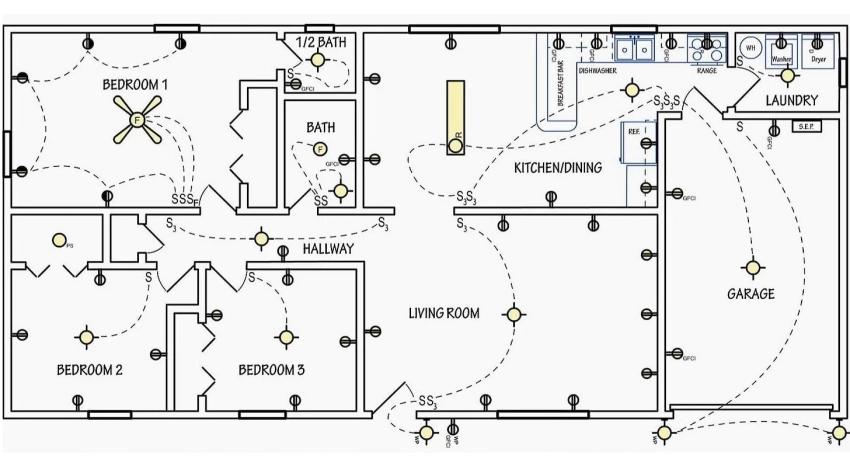

Electrical Shop Drawing

The electrical shop drawings depict electrical systems including power supply, control and security systems, distribution, access, information and communication systems, and interior-exterior lighting.

Building contractors can evaluate accurate electrical layouts with comprehensive shop drawings, eliminating the possibility of overlap of electrical and mechanical systems.

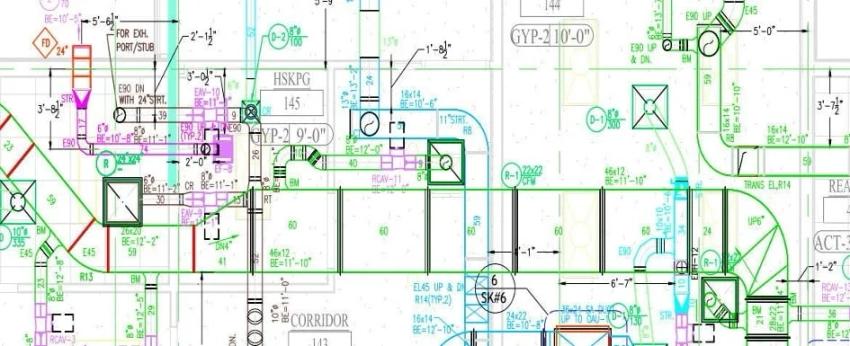

Plumbing Shop Drawing

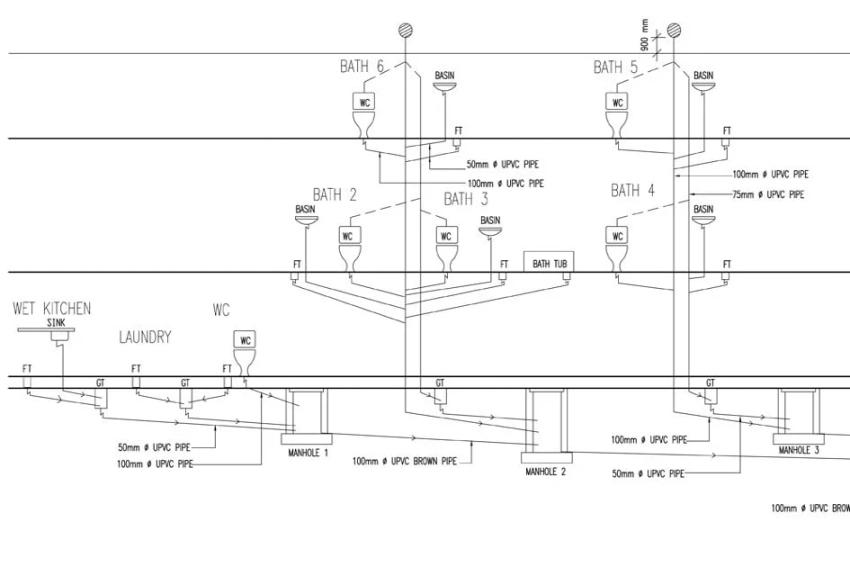

Plumbing shop drawings include piping layouts, drainage system details, and garbage disposals. These drawings specify both fluid and air transport for heating & cooling, fuel gas piping, waste removal system, and potable & non-potable water supply.

High-quality MEP drawings ensure the accuracy of component dimensions and retain the ability to address potential errors or clashes.

Benefits of MEP Shop Drawing Services

Shop Drawing services are a crucial resource for the project stakeholders and the client for smooth execution and future maintenance of the project. Here are a few of the many benefits MEP shop drawings have to offer:

Facilitate Seamless Project Management

MEP Shop drawings include all project details and provide a documented presentation of the systems that are proposed for installation. Such detailed drawings provide project managers with a clear and comprehensive picture of the project requirements, facilitating a smooth execution process.

Sequencing of various procedures and scheduling of trades becomes seamless with shop drawing services. These drawings also reflect amendments made during the review process, making it simpler to track the progress of the project.

Develop Detailed Cost Estimates and Minimize Project Costs

An accurate cost estimation is beneficial for a project as it helps in avoiding budget overruns. Keeping a regular update is mandatory regarding the costs of different components, especially the MEP systems to stay within the required budget.

Cost estimates also help in avoiding overstocking and wastage by providing accurate requirement details. Project visualization before the beginning of construction work also enables the architects to identify areas where they can reduce material cost, and labor costs, and save time spent.

Provide Accuracy and Clarity

A fundamental benefit of producing detailed shop drawings is that they provide accuracy and clarity in the selection of materials and required equipment.

The drawings entail data about performance characteristics, quality control, and physical dimensions of elements along with the detailed layout of the system.

The stakeholders can review and approve this data before construction begins, leading to an outcome synonymous with the client’s requirements and accurate design.

Easy in-Built Project Documentation

The use of BIM for developing shop drawings allows for automatic documentation of all relevant project data. The stakeholders can immediately refer to these documented drawings in case of any emergency during construction workflow and look for the best solution possible to deal with the problem.

MEP shop drawings are also used by licensing authorities to make effective plans and grant permits for a new construction project.

The shop drawings contain valuable records of the materials, equipment, and layouts developed during construction. These records are provided to the client’s facility management team during project closeout.

These records can be used by the client’s team for facility management and maintenance in the future, troubleshooting occurring issues.

Reduces Conflicts and Errors

MEP shop drawings help in identifying potential drawing errors and allow the stakeholders to rectify these errors promptly, minimizing construction delays and costs. There are instances when the layouts of different disciples coincide with each other.

These situations can be identified and solved before they turn into costly on-site errors. Mitigating clashes and errors beforehand reduces the chances of rework, completes work within time constraints, and avoids budget overruns.

Conclusion

A successful project outcome can be pertained to implementing clear processes and procedures by AEC professionals. MEP Shop drawings are not only significant for the construction process, but also determine the success of the project even after construction.

The construction industry can indulge in partnering with experienced professionals and generate accurate and detailed shop drawings for successful project results. Not only material or equipment details, but shop drawing services also ensure safety, quality, and service for architects and fabricators.